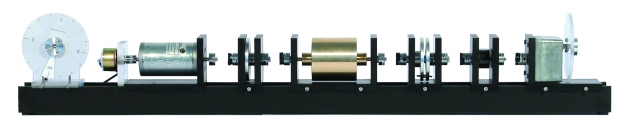

Modular Servo

An easy to reconfigure set-up to demonstrate servo control problems

Modular Servo is designed especially for the study and practical verification of basic and advanced control methods. These includes demonstration of typical variable factors such as friction, damping and inertia as well as a number of position/speed control methods ranging from PID to LQ and time-optimal control.

The DC MOTOR MODULE can be coupled with several other modules. A number of linear and nonlinear mechanical modules are designed to demonstrate the influence of backlash, damping, elasticity and friction. The units may be investigated individually before completing the system. DAMPING MODULE consists of a paramagnetic disc which runs between the poles of a permanent magnet. INERTIA MODULE is equipped with a solid metal roll. A steel baserail provides firm fixing to the modules, enabling imitation of block schematic diagrams, however all electrical connections are performed inside the software. No mechanical skills are required to assemble a working system. Modular Servo operates with a PC-based digital controller. The PC communicates with the position sensor and motor by the I/O board and the power interface. The I/O board is controlled by the realtime software which operates in the MATLAB/Simulink RTW/RTWT environment. The pre-programmed library of controllers and Simulink models supports Modular Servo. A comprehensive range of experiments may be carried out using Modular Servo and associated software.

Hardware:

- motor: DC, 12V, PWM controlled

- power interface

- 7 mechanical modules

- position & speed sensors: incremental encoders tacho-generator

- base rail

- RT-DAC I/O external USB board (PWM control and encoder logics are stored in a XILINX chip)

Dimensions of a single module:

900x100x145 mm